BAUMANN Springs

Spring Konfigurator

The Swiss Baumann Federn AG, headquartered in Ermenswil in the canton of Zurich, has been developing, producing and selling springs and stamped parts at eleven locations around the world for over 125 years. With around 1,400 employees, the company has established a leading international market position and a well-known customer base from the automotive and electrical industries as well as medical technology.

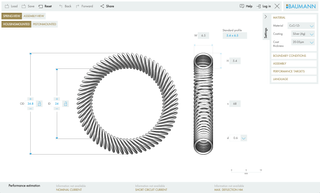

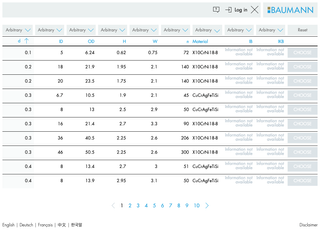

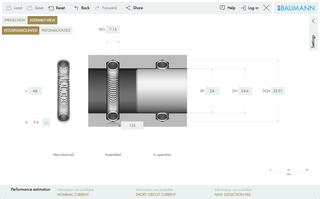

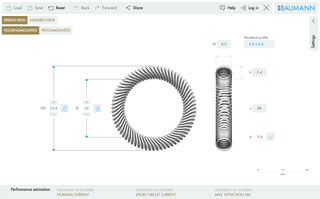

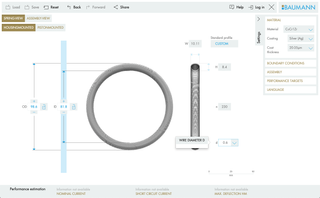

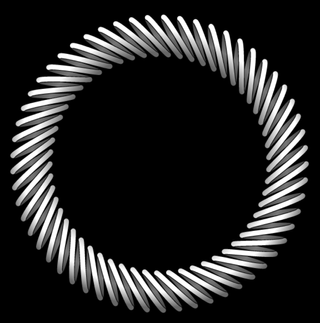

For the dynamically growing and innovative business area of contact elements, kaliber5 conceived, designed and developed a B2B configurator application at the highest technical level. The configurator enables the engineer - be it on the customer or on the supplier side - to design an individually designed and manufactured contact element, a special technical spring, usually is used for power transmission. The user can adapt the product to his needs in an intuitive way and adapt it to his special needs through step-by-step optimization.

The product configurator supports him in this by running a large number of calculations in the background. This always ensures that all parameters are within reasonable and manageable limits. In addition, with each change, the effects on the corresponding performance values of the component are calculated and displayed: the maximum current transfer and the mechanical properties such as the maximum deflection. Based on these calculations, it is even possible to display dynamically generated diagrams that show the physical relationships between the currently selected product parameters and the resulting performance values.

The project was designed and developed in close cooperation with the customer. Due to the complexity and the desired innovative implementation, only a development according to agile methods was promising. In a short conception phase, the product vision was developed using mockups. The detailed conception, implementation and evaluation then took place within the framework of the agile project management framework Scrum in many iterations, the sprints, in order to be able to provide the customer with maximum transparency and optimal user-centered quality of the end product.

The biggest challenge in this project was, on the one hand, to pack the many parameters of this very technical product into a coherent UX concept in such a way that engineers on the customer side can also use the configurator and understand the actual product behind it. An operating concept was deliberately chosen that looks similar to CAD software. In addition to entering values in fields, the user can also interactively drag and drop the product dimensions and change them.

The modern front end ensures that the boundaries between browser-based websites and interactive desktop software merge. On the other hand, the development team was confronted with a product that - even if it may seem simple and plain to the layperson - requires an understanding of a large number of complex mathematical / physical relationships. An example: in order to determine the mechanical properties, calculations in three-dimensional space had to be combined with numerical methods of searching for the zero point. In order to keep the performance and speed of the application high, these values were precalculated and stored with several million data points in a database; a linear interpolation method in four-dimensional space determines the approximate value, which is accurate to several decimal places, in a fraction of a second.

The application has been online since June 2015 and is continuously being further developed.